Maximum number of sheets of 80 g/m² paper. The maximum capacity in this case is 50 sheets.

Tool with metal functional parts

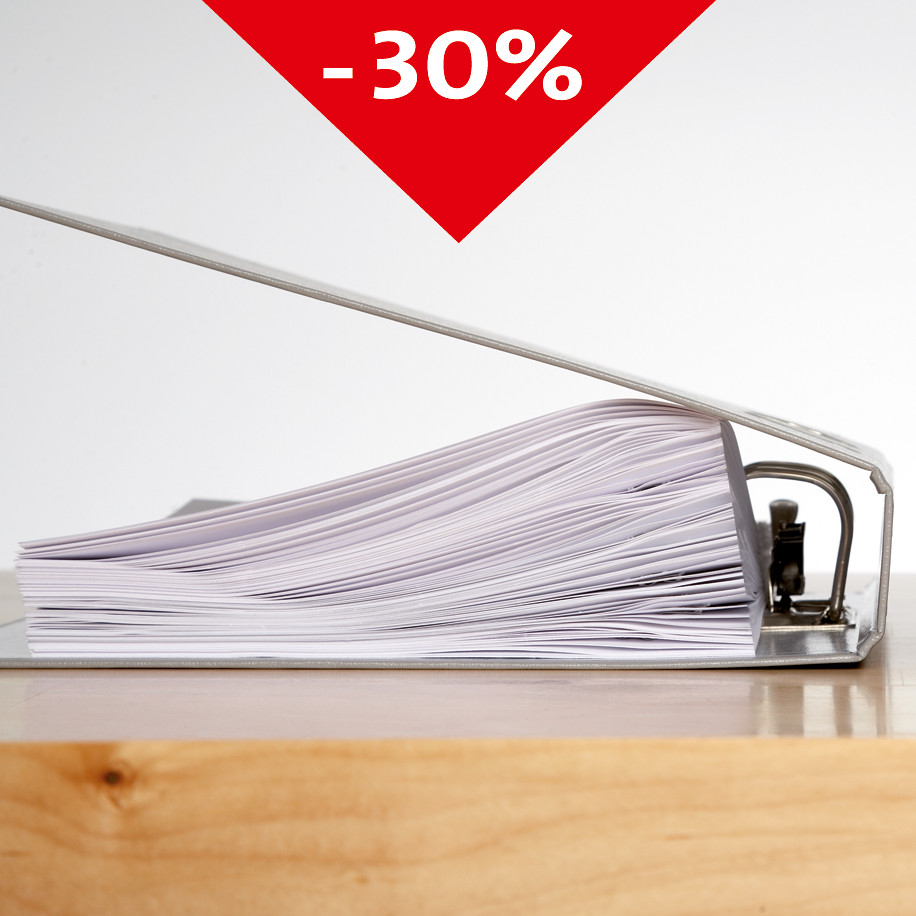

With staple legs resting flat against the paper, flat-clinch stapling cuts filing space by as much as 30 %. The minimum amount of space taken up by staple ends optimises binder capacity.

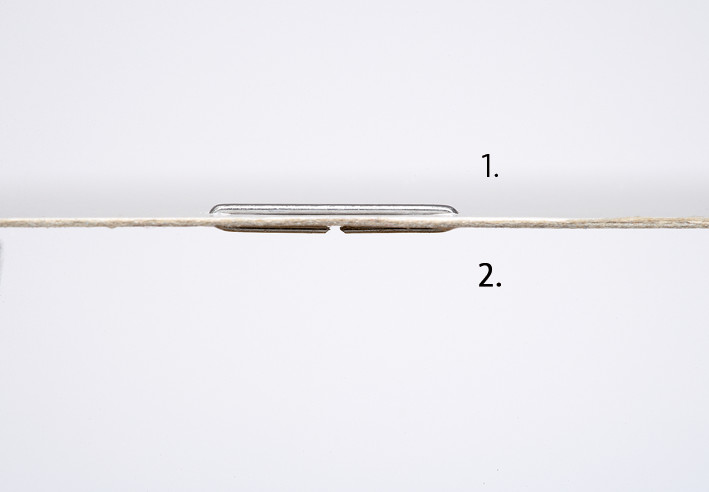

Temporary stapling makes it easy to keep papers together for short periods.The advantage: staples can be removed quickly and easily.

For quick fastening: nailing.

This device can process staples of type 26/6 to 26/8 SUPER. A maximum of 200 staples can be inserted.

Quantity and type of staples used. In this case, 150 staples 24/6–24/8.

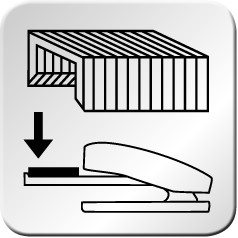

The spring loading mechanism - by pressing a button at the rear of the stapler, the staple magazine is released for front loading.

Maximum stapling depth is 90 mm.

Novus offers a warranty of 25 years when handled in a proper manner.

The quality statement "German Engineering" ensures that a product was developed according to German quality standards by our engineering experts. All Novus products carrying the "German Engineering by Novus" signet are manufactured in our own plants around the world by our own workforce, managed and supervised by our headquarters in Germany.

This machine bears the GS approval of product safety.

The moveable anvil also permits permanent and temporary stapling. Temporary stapling is ideal for short-term fastening. Advantage: easy, fast removal of staples.

The minimum amount of space taken up by staple ends optimises binder capacity. Despite flat-clinch stapling, staples are easily removed from paper with a staple remover.

With stapling legs resting flat against the paper, flat-clinch stapling cuts filling space by as much as 30 %.

With the two-stage stapling action, the staple legs pierce the paper first. The staple ends are then bent over and pressed absolutely flat against the paper.